Why wire EDM?

Wire erosion or wire sparking (called Wire EDM) is a form of metalworking in which a workpiece is processed by means of a moving wire (electrode) under tension. The electricity flows through the electrode and creates sparks that pulverize material into dust at that spot. Since the operation is performed by electricity, all conductive materials can be eroded.

Wire EDM is very accurate, down to 0.001 mm and with surface roughnesses as low as Ra 0.1 µm. Complex shapes, transitions, etc. are easy to program.

Wire EDM technology is constantly evolving. New functions, alignment options, unmanned cycles, improved technology, new clamping methods, but also the programming software is continuously improved (think of feature-based modeling and recognition). We get the most out of this specific technique to create added value for our customers.

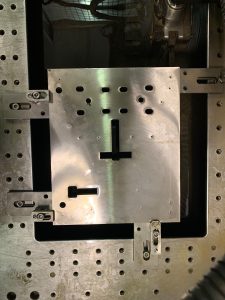

Cases

Parts for extrusion, for cutting dies, for machines. Cooling channels, keyways, molding wheels.

Straight, conical, transitions… everything that can be connected with a line is sparkable for us. We are also happy to accept jobs with angled starting holes.

We think about fixation of the workpiece, the waste pieces, the starting holes, etc.

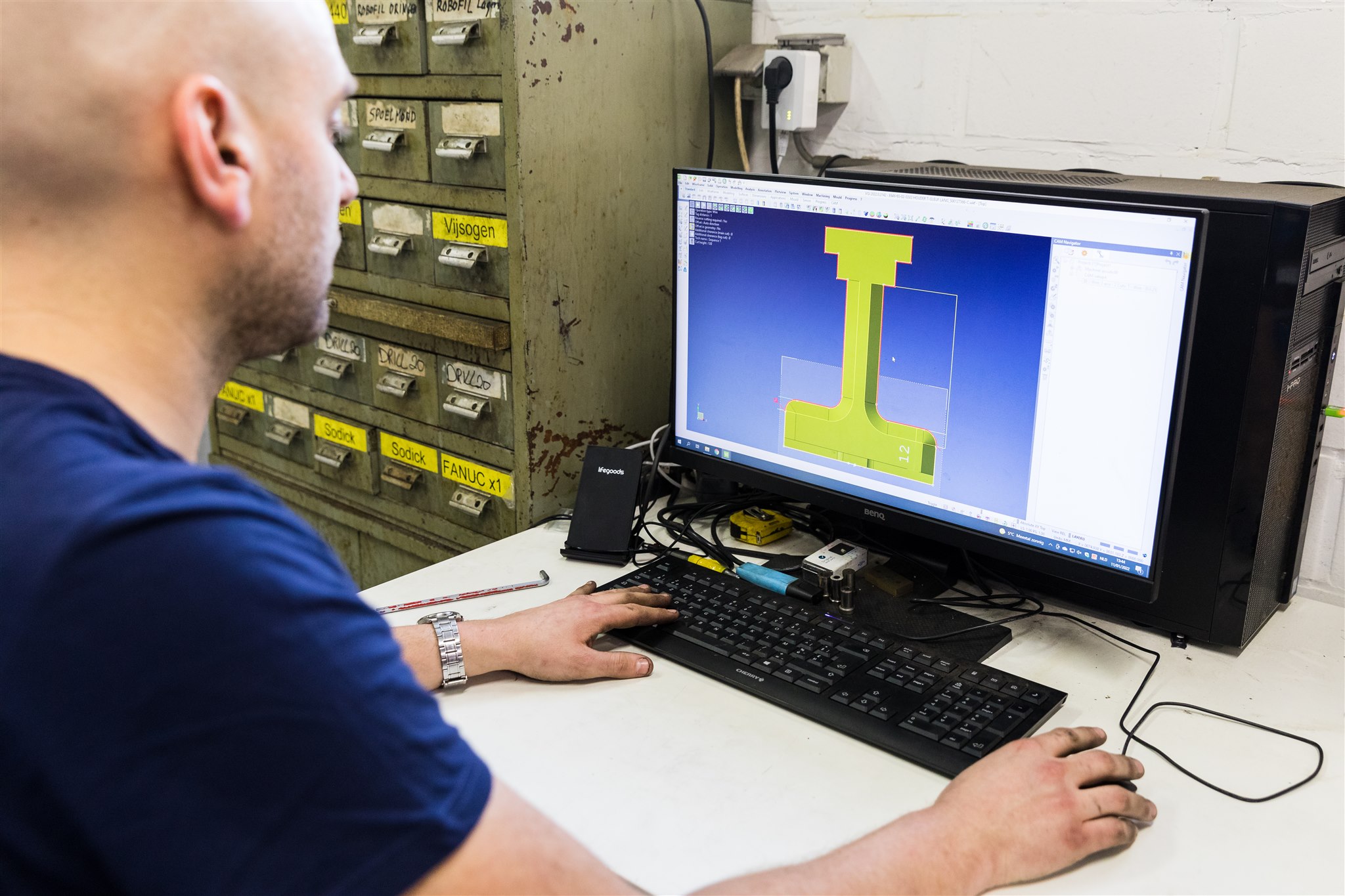

CAD-CAM -> Machine

Our CAD-CAM software package VISI is used throughout all departments of our company, including wire EDM. It contains the module PEPS-wire with all possible options integrated. The feature recognition is very useful for us, so that complex features do not have to be created separately. Every software has its positive and negative sides, but with our thorough training in the package, we have been able to program everything in a fairly simple way. The advantage of a CAD-CAM package is that the programming is uniform, for any machine. Very rarely do we look in the ISO coding of the mail to adjust things that cannot be changed in the package.

If desired, a specific file can also be written for the starting hole spark.

Wire erosion machines

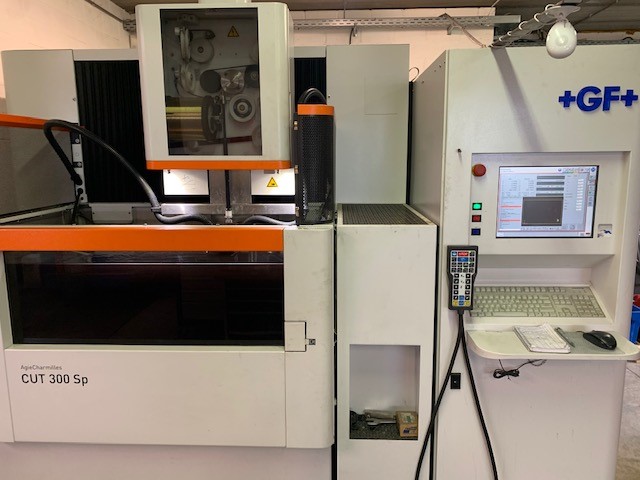

1 – AgieCharmilles Cut 300 Sp

- Our Cut 300 Sp is our workhorse

- Full bath

- max. workpiece dimensions 1200 x 700 x 400 mm

- max. machining dimensions 550 x 350 x 400 mm

- max. load 1500 kg

- Sparks up to 400 mm high

- Conicity up to 30°

- max. finish to Ra 0.1 µm (in 11 sections).

- We can measure the roughness with our own Mitutoyo surf test sj-210

- Own cooling group, with emergency cooling facility

- Remotely monitorable and controllable

2 – Charmilles Robofil 440

- Robofil 440 as a backup for the Cut 300

- Full bath

- max. workpiece dimensions 1100 x 600 x 400 mm

- max. machining dimensions 550 x 350 x 400 mm

- max. load 900 kg

- Sparks up to 400 mm high

- Conicity up to 30°

- max. finish up to Ra 0.3 µm

- We can measure the roughness with our own Mitutoyo surf test sj-210

- Own cooling group, with emergency cooling facility

- Monitorable remotely

3 – Charmilles Robofil 390

- Robofil 390

- Does not work in a full bath, but with high-pressure flushing

- Is mainly used for thinner pieces, whether or not in series

- Has the advantage that the door can be opened much faster compared to the above (after all, you do not have to empty the bath)

- max. load 200 kg

- Sparks up to 220 mm high, but is practically used up to 80 mm

- Conicity up to 20°

- max. finish up to Ra 0.5 µm

- We can measure the roughness with our own Mitutoyo surf test sj-210

- Own cooling group, with emergency cooling facility

- Monitorable remotely

Small hole erosion

Start-hole EDM is a technology in itself, closely related to sink EDM and an ideal complement to our wire EDM machines. We chose to stay with the same supplier as for the wire EDMs. This is useful for spare parts, programming interface, service and general operation.

- GF Drill20

- CNC and programmable via our standard CAD CAM package or by means of DXF read-in to EasyCAM

- Ideal addition to the wire sparkers

- Gives flexibility to our company and our customers, we can now start from hardened material

- Very accurate due to existing measuring cycles

- Working range 300 x 200 x 250 mm

- Max workpiece weight 300 kg

- Powerful 30A generator sparks the finest holes up to 250mm . astonishingly fast

- Most common electrode diameters in stock: from 0.22 mm to 3.0 mm diameter.

Used wires

We work with Bedra wires, because of their circular approach and wide range.

We use wire from 0.15 mm (for fine processing in eg the extrusion technique) to 0.33 mm, where speed is more important. Where possible, we opt for (zinc) coated wires.

Quality, communication and a correct price

The price is calculated based on the expected setup time and the expected unmanned run time. Runtime is estimated by the CAD-CAM package and checked with tables built up through experience (speeds dependent on wire diameter, height, material, number of cuts, conicity, etc.)

You can also contact us for any milling, turning and grinding before or after wire EDM. As a metalworking company, we offer a complete service, with a special passion for mold making and wire EDM.

Request a quote! We answer within the day. Please send a .STP or .DXF/.DWG